By Geoff Bradshaw, Willow-Green Products

The key to a good outcome from any spraying operation is being well prepared, knowing how to do the job, and executing the spray the way you planned it. It is important to start your preparations well in advance of when you need to spray the crops.

Pre-spraying Checks

Here are some of the factors one has to would consider.

- What type of sprayer is to be used knapsack or boom sprayer?

- Is the sprayer in good working order? No leaking hoses or fittings.

- Are the tank, filters, and nozzles all cleaned out after the last application?

- Check for nozzle wear by comparing the nozzle flow with that of a new nozzle at the same pressure. If the flow rate is 10% more than a new nozzle, then nozzles need changing.

‘As a rule of thumb, use fan nozzles for herbicides and hollow cone nozzles for fungicides and insecticides.’

Once you have selected the chemical you are going to apply, ask yourself these questions;

- Have I READ and UNDERSTOOD the label of the chemical selected?

- Is it the appropriate product for the crop, the pest to be controlled, or the timing of the application?

- Is there need to add other chemicals or additives?

Chemical Mixing Procedure

Once you have selected the chemical dosage and total volume for application (water and chemical) based on the recommendations on the label; one then needs to calibrate the sprayer to apply the selected application rate per hectare.

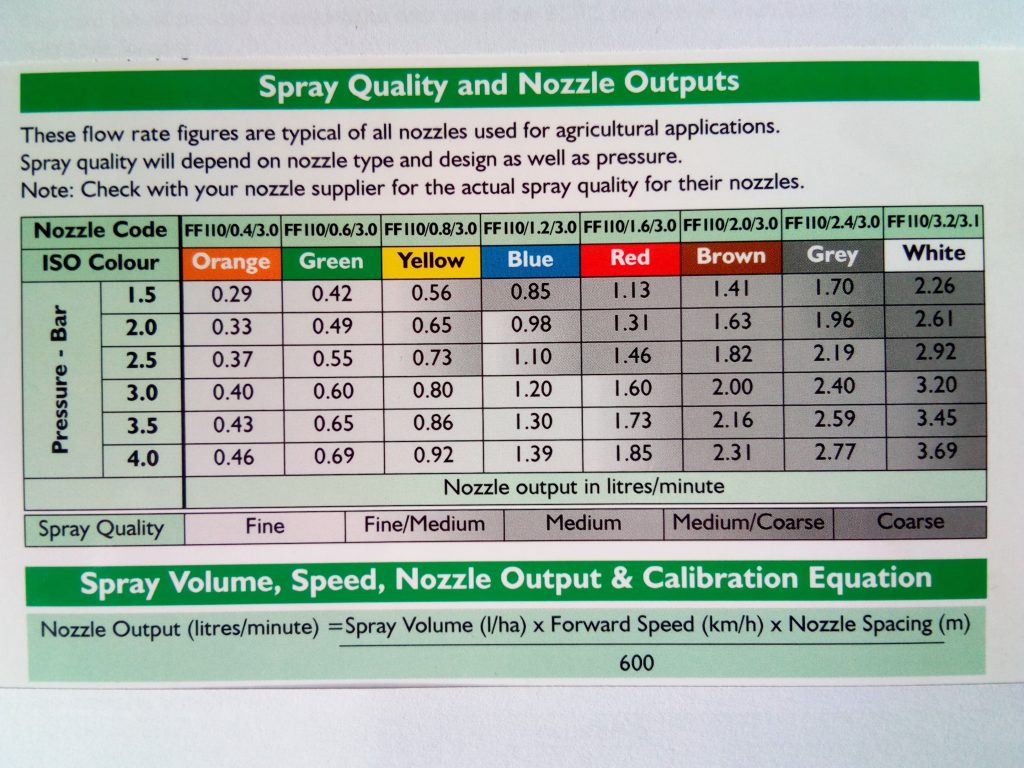

Application rate (lit/ha) x Speed (km/hr) x Spray width (metres) = Nozzle flow (lit/min)

600

Example 200 lit/ha x 4.0 km/hr x 0.9 metres = 1.2 litres/min

600

In this example one could use a blue nozzle at 3 bar pressure or a red nozzle at 1.8 bar pressure.

- If applying a herbicide, it would be best to use a red fan nozzle at 1.8 bar with minimal drift.

- For a fungicide it would be better to use a blue hollow cone nozzle at 3 bars, which would give better coverage of the target.

Calibrating the Equipment

The primary goal with calibration is to determine the actual rate of application in litres per Ha, then to make adjustments if the difference between the actual rate and the intended rate is greater or less than 5% of the intended rate. You will require a tape measure to check distance (speed) and for measuring the spray width, calibration jugs, and a timing device to time the speed and nozzle flow. Practically check the sprayer using water.

Checking the Application Rates

-Speed of the operator or tractor over a fixed distance (a speed suitable for the conditions

and the land/area to be sprayed).

-Spray width–adjust the nozzle or boom height to achieve the correct spray width/ overlap.

– The nozzle flow rate – If the flow rate is not as desired, then the pressure will have to be adjusted (small adjustment) or the nozzles need to be changed (large adjustment).

-Use lower pressures to minimise drift with herbicides. With each type of nozzle there is a range of sizes allowing you to achieve the flow rate you need.

Things to Note When Spraying

– Ensure you have the appropriate protective clothing for the product being applied.

– Are the weather conditions suitable for spraying?

– Avoid windy conditions which can cause spray drift.

– Avoid spraying in hot dry conditions when chemical will evaporate, and the plants are also not receptive to the chemical.

-The success or failure of your pest control spray application will be determined by the quality of the product being applied, the timing of the operation in relation to the pest, the weather conditions, the skill and training of the operator, and the sprayer and its adjustments.

Now you are ready to spray your crop!

Geoff Bradshaw is a Trainer and consultant in Good Agricultural Practice and Pesticide Application. A supplier of appropriate spraying equipment. He can be emailed on bradshaw.geoff@gmail.com

Images provided by Geoff Bradshaw and ZiMunda Farming Magazine